PROFILING

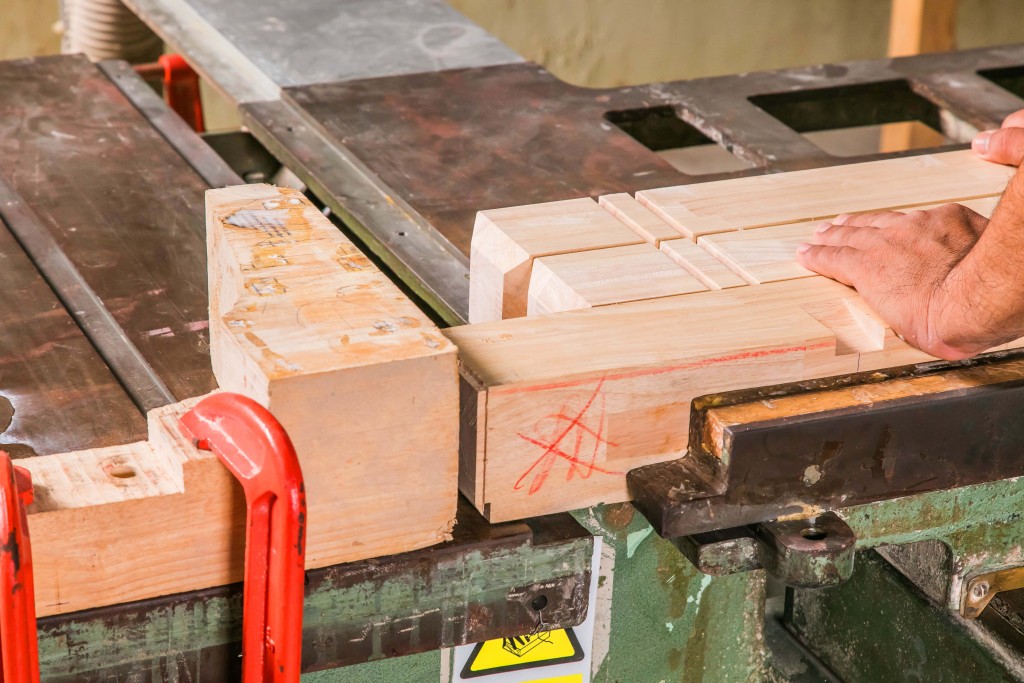

Profiling is one of the most important steps in woodworking. Both housing materials and furniture need accurate profiling parts for beautiful final products. Wood is a natural material and many technical problems may occur during the wood profiling process. The core of successful wood profiling is to have the wood parts are accurately straightened and the angles need to be right after being processed. In order to avoid potential technical errors, it relies heavily on workers’ skills and factory’s management. VIETWOOD is very strong at this process thanks to our skilled workers, high technology factory and experienced management system.

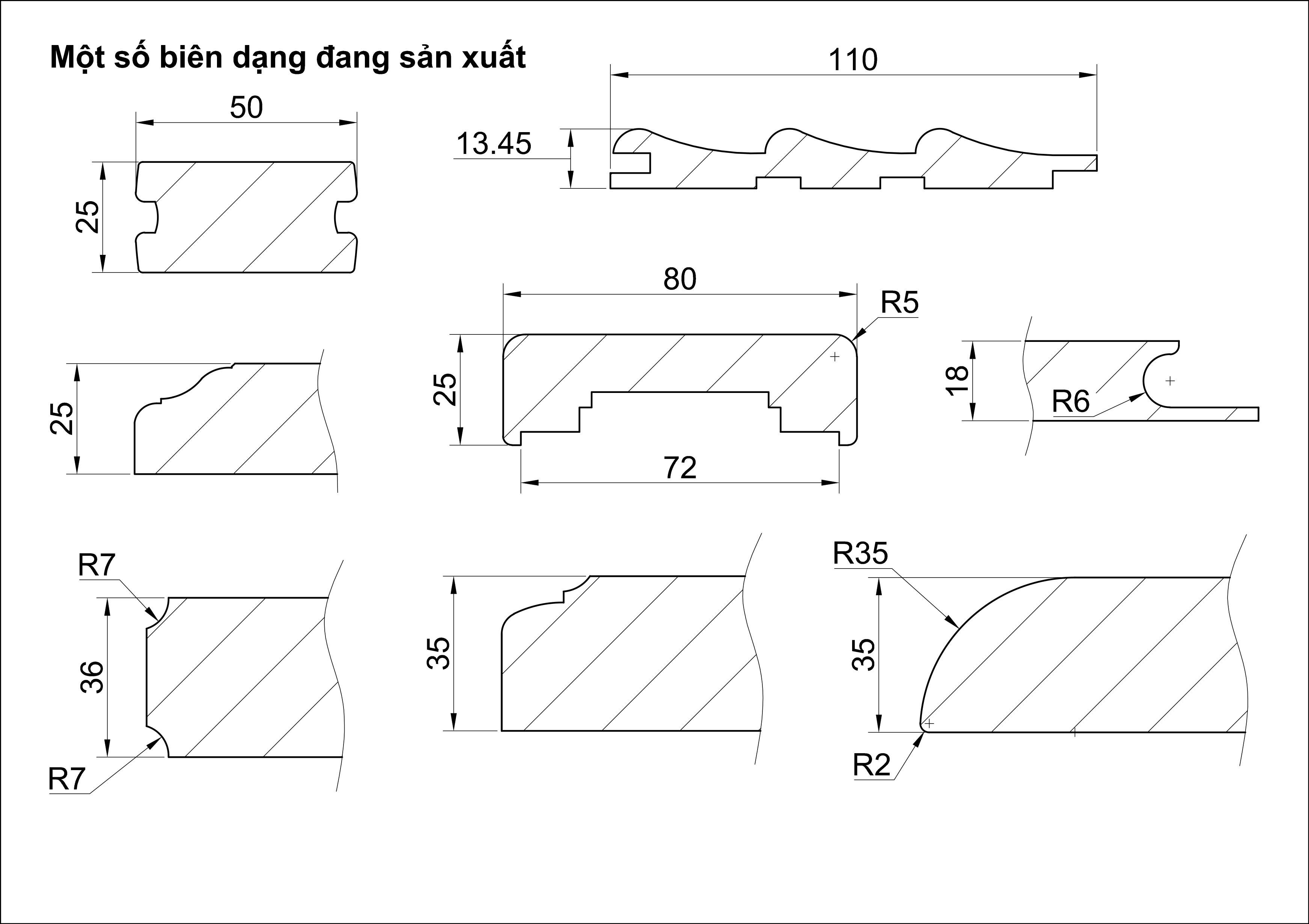

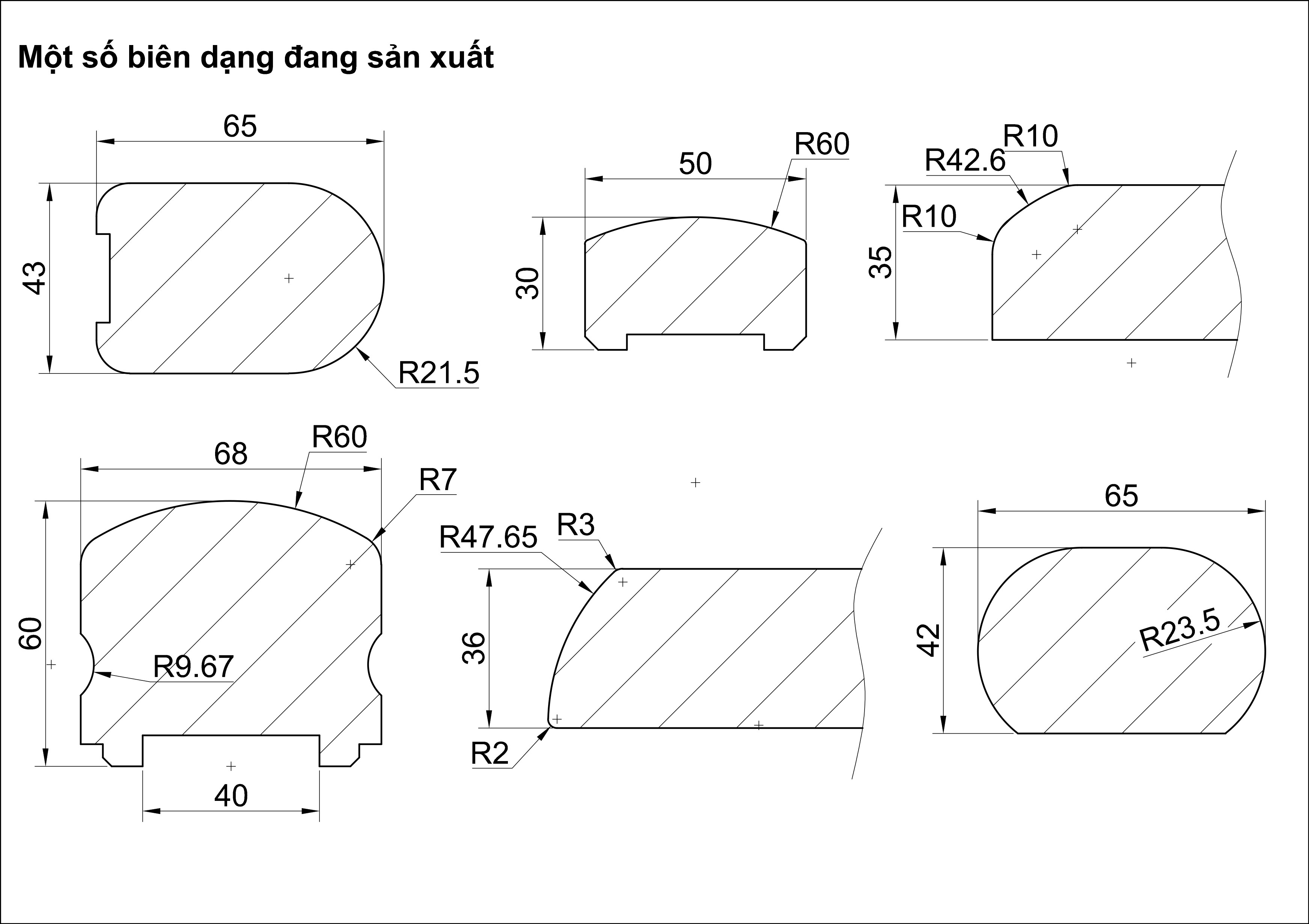

In addition, profiled products have a broad range of difficult shapes. This job not only requires high skills but also the commitment in woodworking jobs of all employees. VIETWOOD has a very strong team who hunger for learning and trying new things. On top of that, VIETWOOD highly invests in modern technology to increase the accuracy of profiling. New machines that are more accurate and efficient, have been installed into VIETWOOD production line in order to increase product quality for many types of profiling such as bevel, chamfer, grooving, molding, drilling, etc.

As a result, we are proud to announce our quality: high profile precision (the tolerance accuracy is up to +-0.5mm), excellent surface quality (qualifying Japanese and European standard). Just give our designing team your drawing or ideas or design criteria, then we come up with the final drawing which developed to final products. Our engineers are proficient in using CNC machine, router … Moreover, they are experts in utilizing either Finger Jointed Board or Solid to profile into not only beautiful shape but also strong wooden structure.