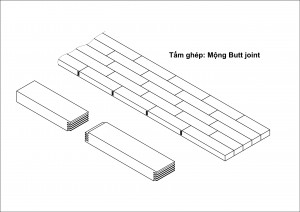

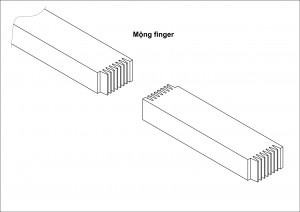

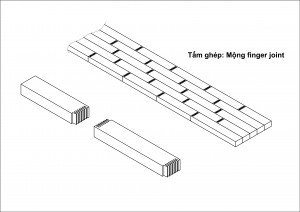

Finger joint laminated board (FJL board) is a solid wood board made by combining many laminas by finger joint or butt joint method into usable lengths strips. These strips are then pressed and laminated together by special glues (2 components adhesive) by hydraulic press machines to become the finger joint laminated board. The laminated board has many advantages that solid wood conventionally does not have. For instance, warping or twisting, which occurs in woodwork manufacturing process could be avoided if we use laminated board instead of solid wood.

VIETWOOD partners with many kiln dry timber suppliers; therefore we can assure stable quality and quantity of rubber wood raw material. After air drying, the moisture of rubber wood sawn timber is around 10% (+-2%).

The length of FJL Board can be up to 5 meters and the width can be up to 1,25m. The glue (AkzoNobel) used for finger joint and lamination by VIETWOOD has F**** (F4Star) certificate. The board after finger jointing and laminating has to pass all the delamination tests at VIETWOOD. Also, we can provide customized products based on requests from customers such as uniform lamina pitch per board, cut to size or edge sanding. These customizations are usually used for DIY products.

Quality control (QC) is one of our strength because we have QC procedure for the whole process of making products and one more QC step for final inspection. ISO 9001-2008 and JAS MALQ/G 01-LF/007 are applied to manage the whole factory in a sufficient condition which can result in cutting down the cost. JAS Label per bundle and JAS Label per piece are also provided if customers required.